EIL R&D – Indigenizing Technologies

EIL has today positioned itself as an organization with an Independent Research Centre and has developed analytical, evaluative, and experimental and scale up capabilities. EIL’s R&D Centre was established in 1988 at Gurgaon with an objective to carry out “Research” aimed at obtaining new knowledge and its application; search alternate for materials, products, processes and services; “Develop” the application of research findings or other knowledge to a plant or design.

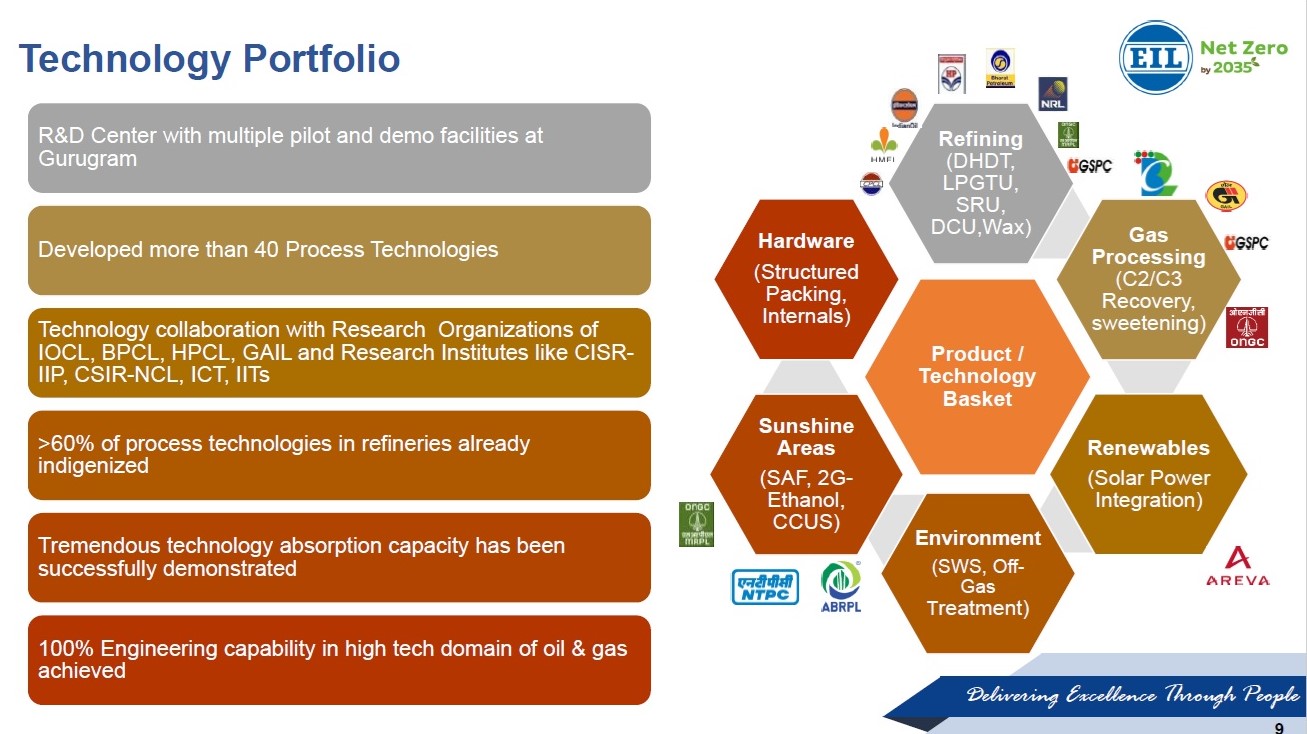

- Commercialized over forty number of technologies for refining, gas processing and petrochemical domains

- Phenomenal conversion rate of patents to commercial applications

- Significant number of publications in international/ Indian journals

- Synergetic arrangements with both industrial and educational research institution in India and abroad. Member of Process Integration Research Consortium (PIRC) at University of Manchester, Fractionation Research Inc, USA, and PSTC group.

EIL Gurugram Office

Research Assets

- Core team of more than 50 technically qualified personnel with professional degrees from prestigious institutions

- Pilot plant facilities include Distillation Columns, Solvent extraction, Catalyst Testing, Hydrodynamic Cavitation apparatus, Coal Attrition study set-up, FCC cold flow model, TBR cold flow model and Coal to Liquid plant with

- Gasifier,Syngas cleaning facility and Gas disposal system

Technologies and Services offered by EIL-R&D

Process Technologies

EIL-R&D through its intellectual wealth has indigenized prominent process technologies combining it with engineering excellence of the organization. Key technologies under different domains are presented below:

| Refineries

CDU / VDU Delayed Coking Visbreaking Aromatic extraction Solvent Deasphalting Solvent Dewaxing Bitumen Blowing Lube Extraction |

Gas Processing

C2/C3 Recovery LPG Recovery C2/C3 Recovery from LNG Glycol Dehydration Gas Sweetening Unit for NG

|

Environment Related

Amine Purification Unit Sour Water Stripper Sulphur Recovery Unit Tail Gas treating Oxygen Enrichment for SRU Ammonia RecoverySO2 removal process

|

EIL-R&D is actively performing role of Licensor where the concepts developed are integrated to prepare a complete knowledge package, which is directly transferable to user for implementation. Some of the technological gems are:

- EngSulf: Claus based sulfur recovery process to convert H2S present in gas stream from Amine Regeneration Unit (ARU) and in Sour Water Stripper Unit (SWSU) to elemental Sulfur

- EngSulfDegas: for removal of H2S and polysulfide dissolved in liquid sulfur of SRU by using proprietary chemicals

- EngTreatL for treatment of LPG using Caustic wash and caustic Regeneration for Removal of Sulphur components (H2S and mercaptan)

- EngCryo for Recovery of Hydrogen from Hydrogen containing Refinery Offgases using Low Temperature Process

- Collaborative offerings: EIL-R&D along with premiere research organizations has many technologies being offered in partnership.

- Technology for Production of Microcrystalline Wax, Regenerative Process for Sulfur Dioxide Removal from Lean Gas Stream is in collaboration with Indian Institute of Petroleum (IIP), Dehradun.

- IndeDiesel, INDADEPTG, indeHex, indJet, indeSelect and indDSK have been developed jointly with Indian Oil Corp Ltd.

Alternative & Renewable Energy

Present forays in fields such as Coal to Liquid (CTL) technology, Process Intensification, Bio-fuels (2nd generation and beyond), integration of solar energy in refinery processes etc.Specialized/ Patented Hardware Development

Capitalizing on knowledge acquired in fields of heat and mass transfer, EIL-R&D developed indigenous models for Furnace used in gas cracking, Steam ejectors, steam traps, trays, igniter device etc.Software solutions/ Specialist studies

EIL-R&D has gained expertise in specialized fields and reduced reliance on foreign institutions. Some of these are:- Computational Fluid Dynamics (CFD)

- Energy Efficiency Studies – Heat and water pinch

- Dynamic Simulation

- Digital tools such as EngRTHtr for fired heater optimization, EngCHP for combined heat and power cycle